Casa Flamenco tequila is a journey of passion and precision, an artistry that has been honed over generations. At the heart of this process lies the finest Weber blue agave, handpicked in the sun-drenched fields of Mexico’s Jalisco region. These sun-kissed agave plants are then expertly harvested and transformed into sweet, succulent nectar through traditional and time-honored methods. Slow-cooked in stone ovens, the agave’s essence is released, creating a rich and complex flavor profile. Crafted with care, cherished by connoisseurs, and designed to elevate your moments of celebration, Casa Flamenco tequila embodies the essence of tradition, innovation, and unparalleled taste.

Harvesting: Our distillery maintains strict standards for the raw sugar content of the agave that is sourced which must fall within a range of 23 to 28 brix. Our agave piñas are trimmed very close to the heart which is crucial in eliminating the oily/waxy taste and texture, contributing to a cleaner fermentation and distillation process, and resulting in a more refined final flavor profile.

Cooking: Our cooking process utilizes traditional stone-walled brick ovens, known as ‘hornos’, to slowly steam roast the agave piña hearts, a process taking 36 to 54 hours. This softens the fibers and transforms the carbohydrates into fermentable sugars, thus preventing the agave from caramelizing. To create our signature flavor profile, we combine brick oven with autoclave cooked agave in a 50/50 ratio.

Shredding & Extraction: Once the agave has been cooked, the sugar is extracted using a shredding machine known as a ‘molino’ or mill. As the agave fibers pass through the milling heads, the sugar-rich agave juice is squeezed out from the fibers. Throughout this process, the fibers and juice are washed with de-ionized and reverse osmosis treated water. The ‘molino’ system is essentially a smaller version of the milling systems used in the sugar cane industry.

Fermentation: We utilize a slow fermentation process that lasts around 60 hours. To start the process, a proprietary selection of natural occurring wild and cultivated yeast is added to the agave juice, and, over time, the fermentation produces a ‘beer’ that contains an alcohol content ranging from five to nine percent alcohol by volume. Generally, a slower fermentation process yields a fuller bodied tequila with a more pronounced agave flavor.

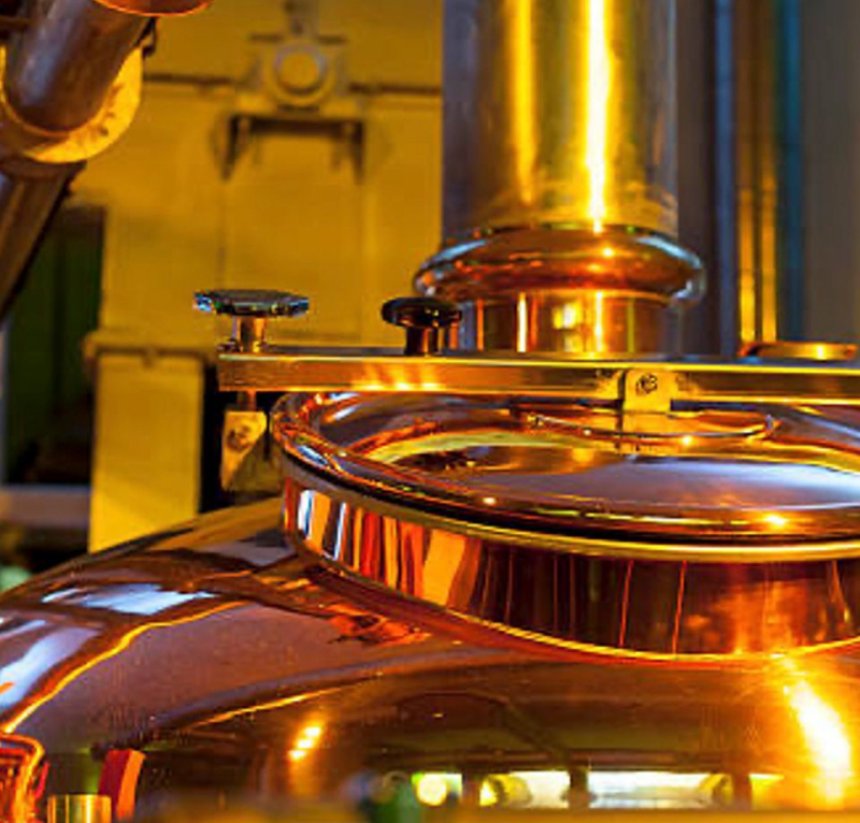

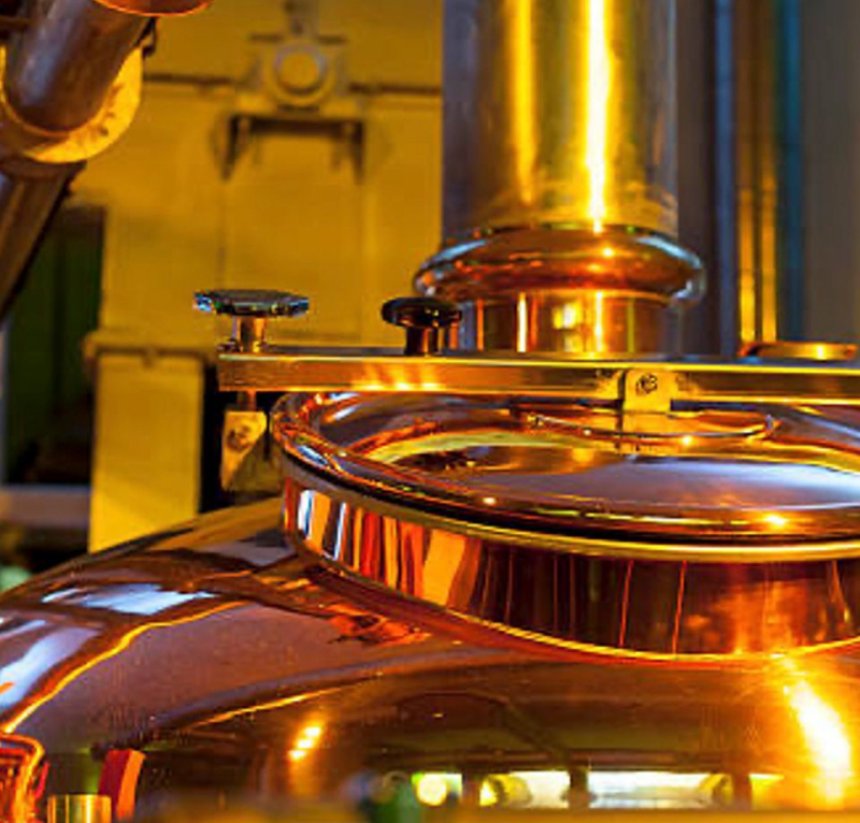

Small Batch Distillation: Our double distillation process utilizes alembic pot stills and takes around six hours. During the first distillation, the concentrate and alcohol are separated from the fermented wort, resulting in an alcohol content of approximately 25% alcohol by volume. The second distillation is used to increase the alcohol content to 40% alcohol by volume (80 proof) which becomes the final product.

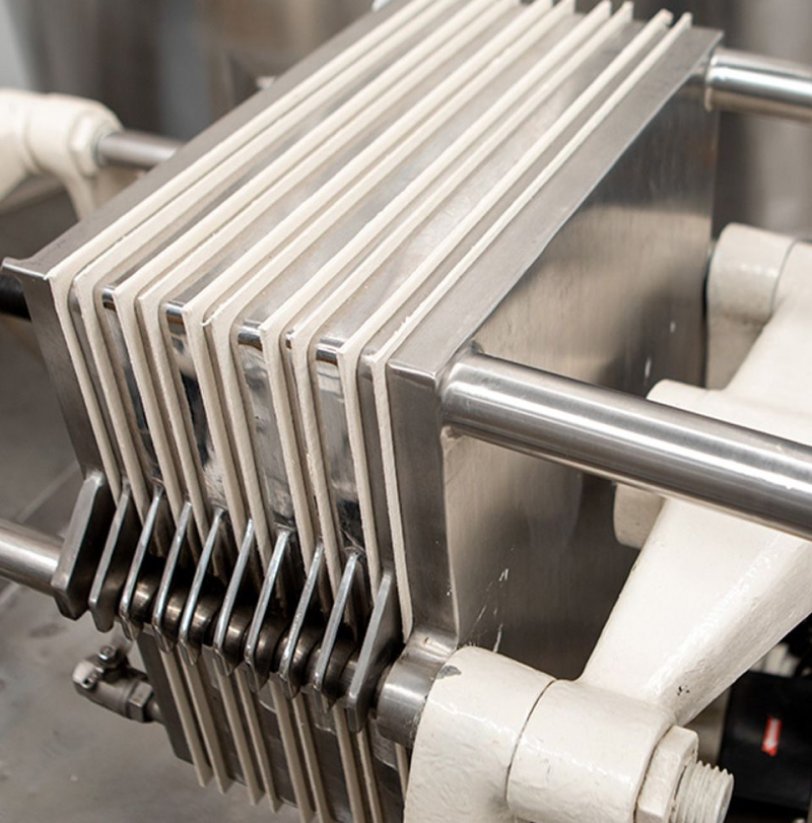

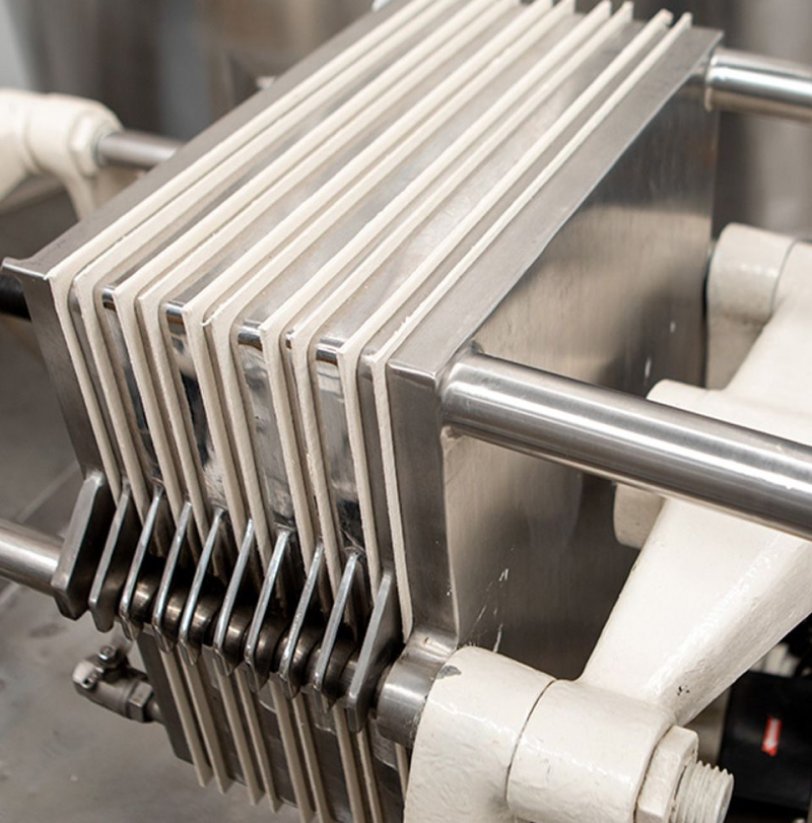

Filtration: We utilize activated carbon and cellulose filters through which our tequila is twice filtered, under cold temperatures to remove excess fatty compounds that give tequila a cloudy appearance. Additional filtration processes are employed to assure that no particulates remain, thus providing our tequila its crystal clear, vibrant finish.

Aging: Our Reposado tequila is aged for up to six months in American white oak barrels that were previously used for aging Tennessee Whiskey. Our barrels are internally charred (roasted) with an open flame for 30 seconds prior to use which ultimately imparts a hint of smokiness to our signature Reposado flavor profile.

Blending: Our blending process includes the addition of demineralized, purified water in order to adjust its alcohol content and assure consistency to our standard of 40% alcohol by volume. Blending concludes the final step in our tequila production process prior to bottling.

Harvesting: Our distillery maintains strict standards for the raw sugar content of the agave that is sourced which must fall within a range of 23 to 28 brix. Our agave piñas are trimmed very close to the heart which is crucial in eliminating the oily/waxy taste and texture, contributing to a cleaner fermentation and distillation process, and resulting in a more refined final flavor profile.

Cooking: Our cooking process utilizes traditional stone-walled brick ovens, known as ‘hornos’, to slowly steam roast the agave piña hearts, a process taking 36 to 54 hours. This softens the fibers and transforms the carbohydrates into fermentable sugars, thus preventing the agave from caramelizing. To create our signature flavor profile, we combine brick oven with autoclave cooked agave in a 50/50 ratio.

Shredding & Extraction: Once the agave has been cooked, the sugar is extracted using a shredding machine known as a ‘molino’ or mill. As the agave fibers pass through the milling heads, the sugar-rich agave juice is squeezed out from the fibers. Throughout this process, the fibers and juice are washed with de-ionized and reverse osmosis treated water. The ‘molino’ system is essentially a smaller version of the milling systems used in the sugar cane industry.

Fermentation: We utilize a slow fermentation process that lasts around 60 hours. To start the process, a proprietary selection of natural occurring wild and cultivated yeast is added to the agave juice, and, over time, the fermentation produces a ‘beer’ that contains an alcohol content ranging from five to nine percent alcohol by volume. Generally, a slower fermentation process yields a fuller bodied tequila with a more pronounced agave flavor.

Small Batch Distillation: Our double distillation process utilizes alembic pot stills and takes around six hours. During the first distillation, the concentrate and alcohol are separated from the fermented wort, resulting in an alcohol content of approximately 25% alcohol by volume. The second distillation is used to increase the alcohol content to 40% alcohol by volume (80 proof) which becomes the final product.

Filtration: We utilize activated carbon and cellulose filters through which our tequila is twice filtered, under cold temperatures to remove excess fatty compounds that give tequila a cloudy appearance. Additional filtration processes are employed to assure that no particulates remain, thus providing our tequila its crystal clear, vibrant finish.

Aging: Our Reposado tequila is aged for up to six months in American white oak barrels that were previously used for aging Tennessee Whiskey. Our barrels are internally charred (roasted) with an open flame for 30 seconds prior to use which ultimately imparts a hint of smokiness to our signature Reposado flavor profile.

Blending: Our blending process includes the addition of demineralized, purified water in order to adjust its alcohol content and assure consistency to our standard of 40% alcohol by volume. Blending concludes the final step in our tequila production process prior to bottling.

Casa Flamenco is an additive free tequila and is produced by Destiladora Del Valle de Tequila – the world’s most awarded tequila distillery.